Linea di perforazione della lamiera

KINGREAL si impegna a fornire ai clienti soluzioni di produzione di linee di perforazione per lamiere della migliore qualità, avvalendosi di tecnologie avanzate e di una vasta esperienza. Per soddisfare la crescente domanda del mercato di prodotti perforati di alta qualità e precisione.

- KINGREAL

- Cina

- informazione

- Scarica

La scelta dei materiali influisce direttamente sulle prestazioni e sulla durata dello stampo. Per gli stampi per micro-punzonatura, la selezione del materiale deve considerare:

Materiali ad alta durezza: per garantire che lo stampo non si deformi ad alte temperature e ad alta pressione, solitamente sono necessari acciai altamente legati o altri materiali ad alta durezza.

Resistenza alla corrosione: durante il processo di punzonatura, la generazione di olio lubrificante e trucioli metallici può causare corrosione dello stampo, pertanto il materiale deve avere una buona resistenza alla corrosione.

Lavorabilità: gli stampi con microfori sono difficili da lavorare e la lavorabilità del materiale influisce direttamente sull'efficienza produttiva e sulla precisione dello stampo.

3. Tecnologia di elaborazione

La tecnologia di lavorazione dei microfori è la chiave per ottenere una punzonatura ad alta precisione e deve affrontare principalmente le seguenti sfide:

Tecnologia di lavorazione di precisione: sono necessarie attrezzature di lavorazione ad alta precisione, come macchine utensili CNC, taglio laser, ecc., per garantire che le dimensioni e la forma dello stampo soddisfino i requisiti di progettazione.

Fasi di lavorazione complesse: la fabbricazione di stampi microforati solitamente prevede più processi, tra cui taglio, molatura, trattamento termico, ecc. e qualsiasi errore in qualsiasi processo può causare difetti nel prodotto finale.

Elevati requisiti tecnici: gli operatori devono possedere una vasta esperienza e competenza per controllare efficacemente la lavorazione e garantire la precisione e le prestazioni dello stampo.

4. Controllo di qualità

Nel processo di fabbricazione degli stampi microforati, il controllo qualità è fondamentale e si riflette principalmente in:

Standard di collaudo rigorosi: ogni stampo deve essere sottoposto a severi test di forma e dimensioni per garantire che soddisfi le specifiche di progettazione.

Meccanismo di feedback: raccolta e analisi tempestiva dei dati durante il processo di produzione per apportare modifiche in tempo reale allo stampo e garantire la stabilità e la coerenza della produzione.metal ceiling perforation line, KINGREAL has also designed a coil to coil perforation line and a sheet metal perforation line according to different punching processes.

|  |

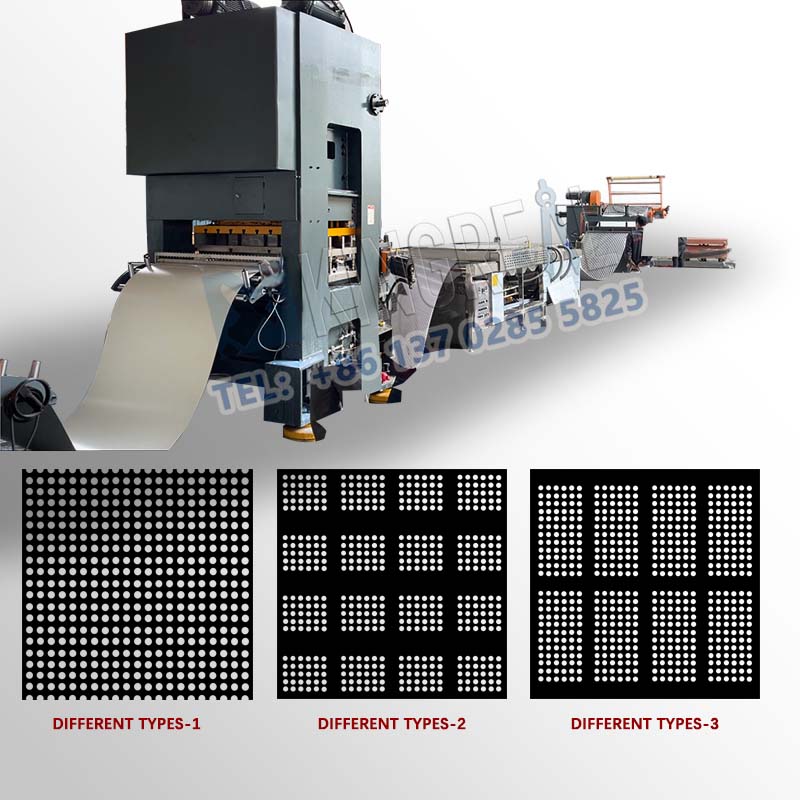

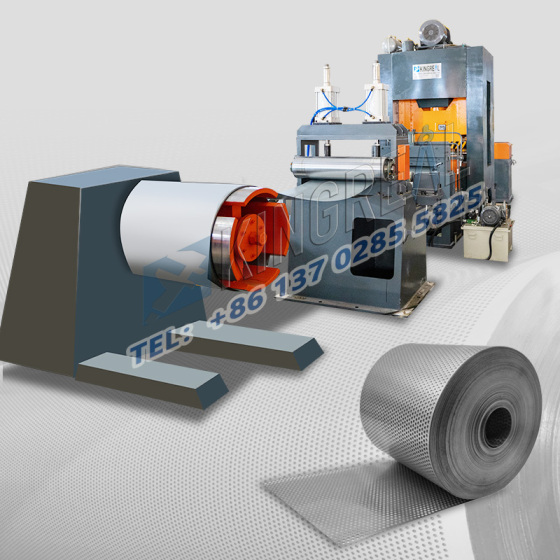

Coil to coil perforation line: The main function of KINGREAL coil to coil perforation line is to wind up the metal coils that have been punched, ensuring that the metal surface is not scratched during transportation and storage, and at the same time facilitating subsequent secondary processing. | The perforated metal machine with cutting is another important equipment of KINGREAL, focusing on the precise cutting of perforated metal coils to meet customers' requirements for finished product length. |

Working principle: The workflow of the coil to coil perforation line is relatively simple but efficient. First, the decoiler unwinds the metal coil and corrects it through the leveler to ensure the flatness of the material. Subsequently, the punching machine punches according to the preset parameters and punches the required hole shape and aperture on the material. Finally, the perforated metal material is wound up by the recoiler to form a roll that can be transported and stored. | Working principle: The workflow of the sheet metal perforation line is also simple and efficient. First, the decoiler unwinds the metal coil and corrects it through the leveler. Then, the punching machine punches according to the preset parameters. Finally, the perforated material enters the cutting station and is precisely cut according to the length set by the customer to form the final product. |

Main components: -Decoiler -Precision straightener -Punching press -Recoiler

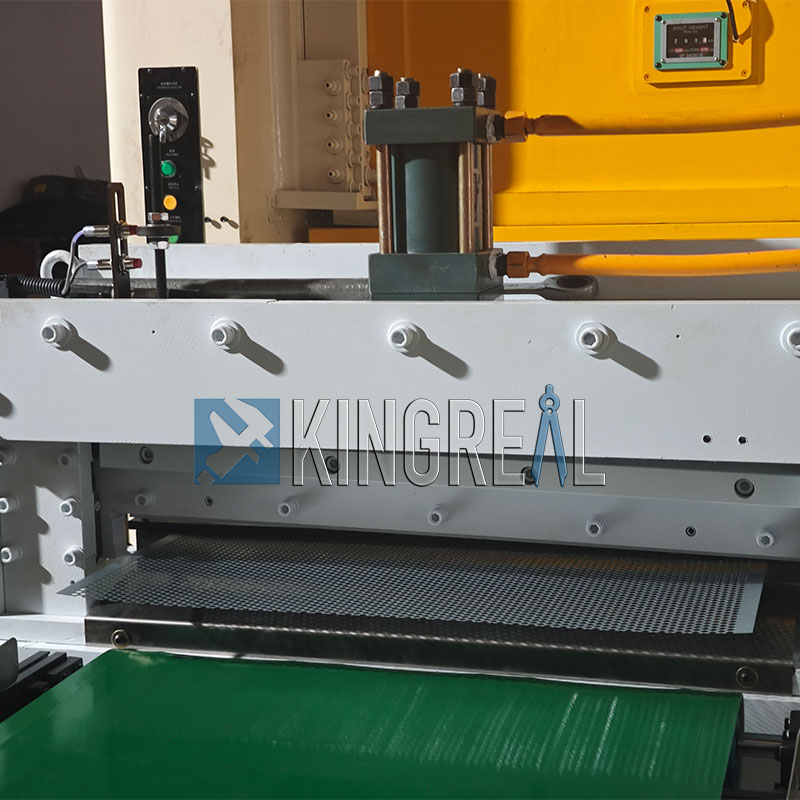

*Recoiler: The recoiler rewinds the perforated metal coil to form a neat roll. The equipment is exquisitely designed to effectively avoid scratches or damage to the metal surface during the winding process, and it is also convenient for subsequent transportation. Through the automated workflow, KINGREAL coil to coil perforation line significantly improves production efficiency, reduces the need for manual intervention, and reduces human errors. | Main components: Decoiler Precision straightener Punching press Cutting station

*Cutting station: The cutting station is the core part of the Sheet Metal Perforation Line, which can accurately cut the perforated metal coil according to the length preset by the customer. This process ensures that the size of each finished product meets the requirements, which is convenient for subsequent processing and use. |

Different Applications of Coil Perforation Lines

KINGREAL sheet metal perforation lines have a wide range of applications and can meet the needs of various industries. Here are some common industries and their specific finished products:

Construction industry: perforated wall panels, partition materials

Automotive manufacturing: perforated filter elements, silencers

Electronic products: perforated panels, radiators

Home appliance industry: perforated trays, ventilation nets

Environmental protection industry: perforated screens, wastewater treatment equipment

Whether it is a large enterprise or a small studio, KINGREAL sheet metal perforation lines can provide efficient and reliable solutions to help customers improve their production capacity.

KINGREAL Sheet Metal Perforation Line Innovation - Micro Punching Technology

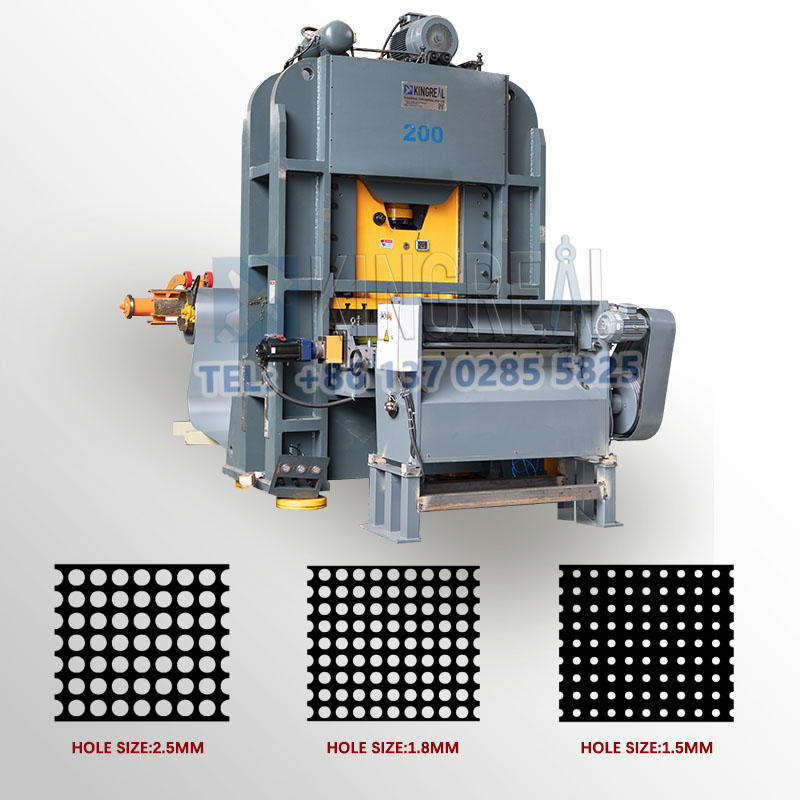

In order to remain competitive in the industry, KINGREAL continues to work on technological innovation. KINGREAL has made significant progress in micro punching technology and successfully provided customized solutions for customers in Greece and Morocco.

|  |

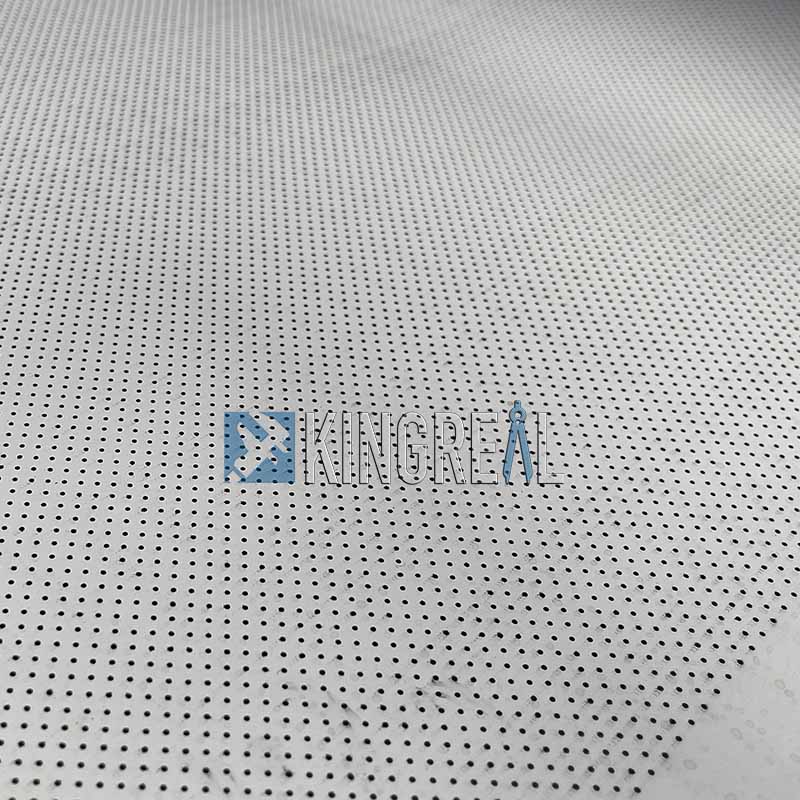

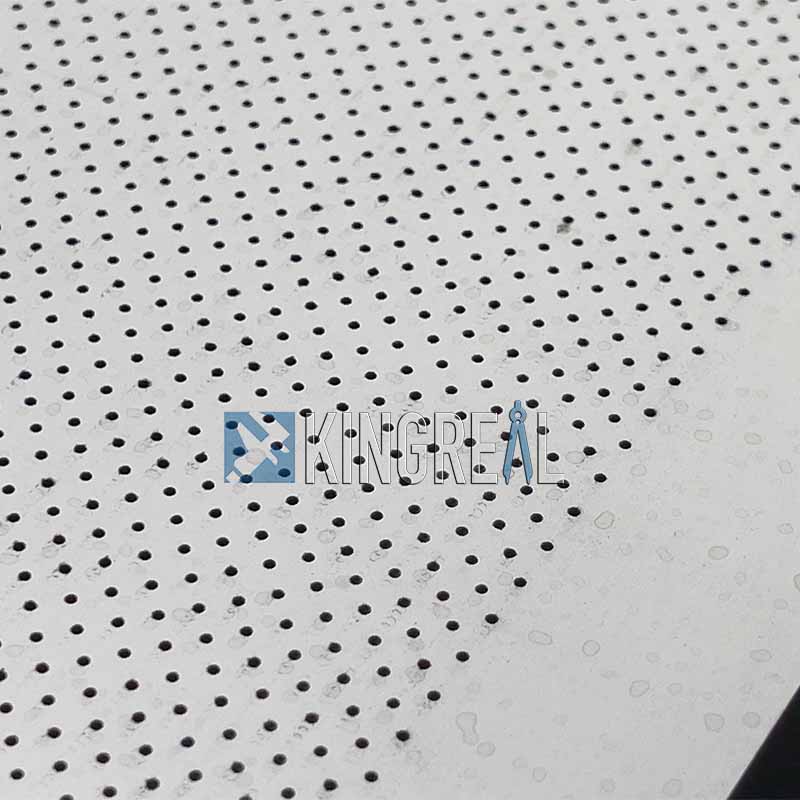

-Greek case- For Greek customers, KINGREAL sheet metal perforation line is able to punch out micro holes with a diameter of only 1.0mm. This technological breakthrough not only meets customers' demand for high precision, but also demonstrates KINGREAL strong strength in the field of micro-punching. | -Moroccan case- For Moroccan customers, KINGREAL sheet metal perforation line can achieve micro-holes with a diameter of 1.5mm. This technology also faces great challenges, because micro-holes have extremely high requirements for the manufacturing of punching dies. |

*Technical Difficulty Analysis

The manufacturing difficulty of micro-holes is mainly reflected in the design and processing of punching dies. The common hole diameters on the market are 1.8mm and 2.5mm, and KINGREAL has successfully developed holes with smaller diameters, thanks to the continuous efforts and innovative thinking of KINGREAL engineers. During the research and development process, KINGREAL engineers first conducted an in-depth analysis of the existing punching dies to understand their shortcomings in the production of micro-holes. Subsequently, through the optimization of material selection, mold design and processing technology, the successful manufacture of micro-punching dies was finally achieved.

*Design and manufacturing process of micro-punching dies:

1. Punching die design

The design requirements for micro-holes are very strict, especially in terms of hole diameter and hole spacing. KINGREAL engineers need:

Accurate calculation: The size of micro holes is very precise, usually 1.0mm and below, and any slight deviation may result in unqualified products.

Complex geometry: In addition to standard circular holes, micro punching dies also need to be able to support holes of various shapes, which places high demands on the design complexity of the die.

Mold strength: Micro hole dies are subjected to great pressure during the stamping process, so the strength and wear resistance of the mold material must be ensured to prevent deformation or damage during the production process.

2. Material selection

The choice of materials directly affects the performance and service life of the mold. For micro punching dies, the material selection needs to consider:

High hardness materials: To ensure that the mold does not deform under high temperature and high pressure, high alloy steel or other high hardness materials are usually required.

Corrosion resistance: During the punching process, the generation of lubricating oil and metal chips may cause mold corrosion, so the material needs to have good corrosion resistance.

Processability: Micro hole dies are difficult to process, and the machinability of the material directly affects the manufacturing efficiency and precision of the mold.

3. Processing Technology

The processing technology of micro-holes is the key to achieve high-precision punching, and it mainly faces the following challenges:

Precision processing technology: High-precision processing equipment, such as CNC machine tools, laser cutting, etc., is required to ensure that the size and shape of the mold meet the design requirements.

Complex processing steps: The manufacture of micro-hole molds usually involves multiple processes, including cutting, grinding, heat treatment, etc., and any error in any process may lead to defects in the final product.

High technical requirements: Operators need to have rich experience and expertise to effectively control the processing and ensure the accuracy and performance of the mold.

4. Quality control

In the manufacturing process of micro-hole molds, quality control is crucial, mainly reflected in:

Strict testing standards: Each mold needs to be strictly tested for size and shape to ensure that it meets the design specifications.

Feedback mechanism: Timely data collection and analysis during the production process to make real-time adjustments to the mold to ensure the stability and consistency of production.

2. Selezione del materiale